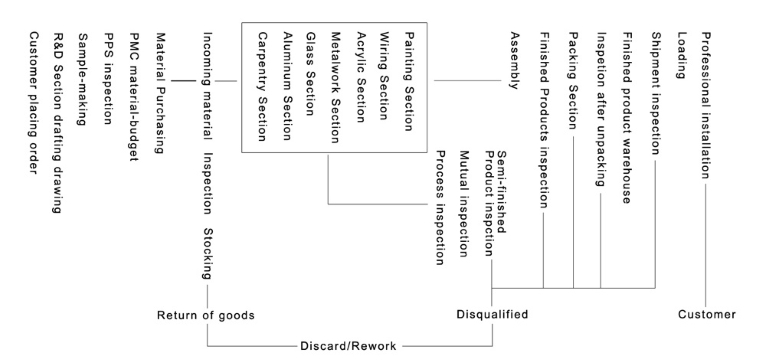

Our corporate quality control system is registered to the ISO 9001:2008 standard. Bevis has cultivated a culture that is dedicated to continuous improvement, which enables our company to consistently design, fabricate and finish parts of the highest quality. Our computerized quality records provide traceability and accountability.

Besides, Bevis is certificated with SGS, UL and more.

There is a quality control manager in each process, no matter for wood department or the metal department.

The in-process statistical quality control is proceeded, all the employees have to pass the formal training test.

All the products are 100% inspection before packing, the inspectors measure against the specification with the production instruction. The inspection report should be signed and reported.

For each project, there is a assigned manager to follow up all the process. If there is any unforeseen circumstance occurs, the project manager will notice the engineer and sales person. The engineer and project manager will deal with the circumstance. If the delivery date will be affected, the sales staff will send e-mail to the client.

Either you bring us the idea/design or we can provide design recommendations.

|

|

|

|